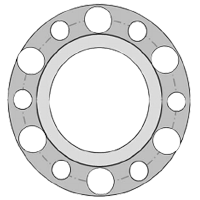

SAE Split flange Halves, havit, high pressure flanges Dealer, reducing flanges, raised-edge flanges, hydraulics, SAE Flanges Stockist, Stainless Steel SAE Hydraulic Flanges, CS SAE Flange and SAE Havit, SAE Split Flange FLAT Supplier in Mumbai, India.

Rotating-beam fatigue strength at temperatures to 1600 Degree F (870 Degree C) of annealed, cold-drawn rod is shown. Titanium nitrides, titanium carbides, and chromium carbides usually seem within the alloy’s microstructure. The nitrides are strong in any respect temperatures under the melting factor and are consequently unaffected through warmness treatment. Chromium carbides precipitate are in company of the alloy at temperatures among a 1000 Degree F and 2000 Degree F (540 Degree C and 1095 Degree C). Consequently, Alloy 20 SAE Weld Neck Pipe Flanges is much like different austenitic alloys in that it may be rendered at risk of intergranular corrosion (sensitized) in positive competitive environments through publicity to temperatures of a thousand to 1400 Degree F (540 Degree C – 760 Degree C).

A critical asset of this alloy is its relative freedom from chloride stress-corrosion cracking. Extensive research of stress-corrosion cracking of austenitic alloys in chloride solutions have proven that the tendency to crack decreases by means of growing nickel content material of alloy. For example, it's miles taken into consideration to be resistant to chloride-ion stress- corrosion cracking. It may be made to crack in excessive laboratory tests; however Titanium Alloy SAE Reducing Pipe Flanges has such excessive resistance that it's miles generally used to replace materials which have failed in provider from stress-corrosion cracking

Specification Chart of SAE Flange

| Specifications | SAE Flanges |

|---|---|

| Size | ½" (15 NB) to 48" (1200NB). |

| Dimension Standard | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Class / Pressure Rating | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| SAE Flange Standard SAE | 6Bar 10Bar 16Bar 25Bar 40Bar |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Flange Face Type | Flate Face (FF), Raised Face (RF), ANSI B16.5 (RTJ) |

| Special design | As per your drawing AS, ANSI, BS, DIN and BS 15 NB (1/2") to 200 NB (8") Equal and Reducing Configurations BS Threaded Flange, Socketweld Flange, Slip-On Flange, Blind Flange, Weld Neck Flange |

| DIN 2527 Flanges Standard | ANSI DIN, GOST, Korean, SAE, BS, AS2129, Korean, EN, SABS, NFE etc. BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, SAE Flange, Korean/ KS Flange, BS4504 Flange, GB Flange, Korean Flange, GOST Flange, PSI Flange AS 2129: Table D; Table E; Table H B.S: BS4504 , BS3293, BS1560, BS10 ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, Korean, Custom Drawings American standard (ANSI) ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 British standard (BS) German (DIN) Any other specilised flanges The other standard: DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 |

| Testing and Documents | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports |

| Packing | Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests |

Material Grades of SAE Flanges

| Stainless Steel SAE Flange | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, SAE 1.4301, SAE 1.4306, SAE 1.4401, SAE 1.4404, SAE 1.4308, SAE 1.4408, SAE 1.4306, SAE 1.4409 |

| Carbon Steel SAE Flange | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, SAE 1.0402, SAE 1.0460, SAE 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Alloy Steel SAE Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium SAE Flanges | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper SAE Flanges | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel SAE Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Inconel SAE Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Class 150 ANSI B16.5 Flanges |

| Hastelloy SAE Flanges | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel SAE Flanges | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 SAE Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium SAE Flanges | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Alloy SAE Flanges | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex Steel SAE Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex SAE Flanges | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy SAE Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 SMO SAE Flanges | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, SAE 1.4547 |

| Nimonic SAE Flanges | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Brass SAE Flanges | 3602 / 2604 / H59 / H62 / etc. |

| Other SAE Flanges material | Tin bronze, Alumunum bronze, Lead bronze |

View Thickness Table Of SAE Butt Weld Flanges, We have Global sales network for SAE Flange Clamp metric tapped, Wide Stockist Of SAE Flange In India.

Check available Sizes of SAE Flanges, Ask For Ready Stock of SAE Buttweld Flange, SAE Flanges in Mumbai, India.

BAGODA

Quick ContactReady Stock SAE Flanges

- SAE Blind Flange Counter Stockholder

- SAE T-Block Flange Connectors

- SAE Weld On Flange Counter - SCH.80 (XS)

- SAE L-Block Flange Connectors Manufacturer

- SAE Blind Flange

- SAE Female Threaded Counter-Flange with NPT-Thread

- SAE Female Threaded Flange Counter with UN/UNF-Thread

- SAE 90° Socket Weld Flange

- SAE Female Threaded Flange with NPT-Thread

- SAE Weld On Flange Counter - SCH.XXS

- SAE Female Threaded Flange with UN/UNF-Thread

- SAE 90° Female Threaded Flange with UN/UNF-Thread

- SAE Distance Flange with Test Point 90°

- SAE Socket Weld Flange Distributor

- SAE Female Threaded Flange with BSPP-Thread

- SAE Weld On Flange Counter - SCH.160 Supplier in Mumbai

- SAE 90° Female Threaded Flange with BSPP-Thread

- SAE Weld On Flange

- SAE 90° Female Threaded Flange with NPT-Thread

- SAE Weld On Flange - SCH. XXS Stockist

- SAE Socket Weld Counter-Flange

- SAE Female Threaded Counter-Flange with BSPP-Thread

- SAE Weld On Flange- SCH.160

- SAE Socket Weld Flange flat 500 PSI

- SAE Weld On Flange Counter

- SAE Socket Weld Counter-Flange flat 500 PSI Exporter

- SAE 90° Weld On Flange Manufacturer

Export Destinations For SAE Flanges

MIDDLE EAST Saudi Arabia |

AFRICA Nigeria NORTH AMERICA Usa |

EUROPE Russia |

ASIA India SOUTH AMERICA Argentina |