UNS S31803 Socket weld Flanges, UNS S31803 Long Weld Neck Flanges, DIN 1.4462 SORF Flanges Supplier in Mumbai, India.

It is utilized in Kitchen utensils and desk wear, Architectural (trim, drainage products, typhoon door frames), Automotive (trim, wheel, covers), etc. Typical makes use of this Duplex Steel WNR 1.4462 Socket Weld Flanges encompass springs, structural parts, trailer bodies, diaphragms, utensils, etc. High strength mixed with amazing corrosion resistance makes it appropriate for an extensive variety of applications in sectors along with aerospace, rail and car. The cold hardening variety of this metallic is improved. It is nicely proper to welding and forming and drawing. It isn't always heat-treatable for hardening functions and is non-magnetic as annealed, however barely magnetic following cold working.

Intermediate annealing on this metallic simplest serves to be lessen the hardness and consequently ultimate properties. It is utilized in Conveyor Belts, Home and business appliances, Mass transit systems, and extra. It is likewise utilized in architectural and car trim, hose clamps, wheel covers, roofing products, kitchen utensils, etc. Alloy UNS S31803 Forged Flanges is an excessive strength austenitic alloy by means of having correct ductility properties whilst cold worked. It has correct corrosion resistance and is likewise used in lots of meals service applications. It gives better tensile strength ensured via little or no lack of ductility. It is used for applications in which an easy ornamental end isn't always required.

Material Specification Chart of Duplex Steel S31803 Flanges

| Size Chart | 1/2" (15 NB) to 48" (1S31803NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Duplex Steel S31803 Flanges Manufacturing Standards

| American Standard | Standard Code | ANSI ASME SA182 | ANSI ASME B16.5 | ASME – B 16.47 | ASME – B 16.36 | ||

|---|---|---|---|---|---|---|---|

| Standard Name | Forged Flanges | Slip on flange, Welding neck flange, Blind flange, Threaded flange, Lap joint flange, RTJ flange | Welding neck flange, Blind flange | Welding neck flange Slip on flange | |||

| German Standard | DIN 2527 | DIN 2573 / 2576 | DIN 2673 | DIN 2641 / 2642 | DIN 28115 | DIN PN10, PN16 | DIN PN20, PN25 |

| Blind Flanges, BLRF | Flat Flange for Welding (Slip On) | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) | Lapped / Loose (Lap Joint) Flanges Plain Collars | Long Neck Welding Flanges | PN10 Flanges, DIN PN 10 Flanges, PN16 Flange | PN20 Flanges, DIN PN 25 Flanges | |

| Japanese Standard | JIS B2220 | JIS B2291 | JIS 5K, 10K | JIS 16K, 20K | JIS 30K, 40K | ||

| Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | Slipon plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange (TR)/ Itegral flange (IT) Blank flange (BL) | 5K SORF Flanges, 10K SOFF Flanges | 16K Blind Flanges, 20K BLRF Flanges | 30K Slip on Flanges, 40K Blind Flanges | |||

| Italian Standard | UNI FLANGES | ||||||

| Plan flanges (2276, 2277, 2278, 6083, 6084) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) Lapped flanges (6088, 6089, 6090, 2999, 2300) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) threaded flanges (2253, 2254) | |||||||

| British Standard | BS 10 Table D | BS 10 Table E | BS 10 Table F | BS 10 Table H | |||

| BS 10 Table D Flanges, Table D Pipe Flange | BS 10 Table E Flanges, Table E Pipe Flange | BS 10 Table E Flanges, Table E Flanges | BS 10 Table E Flanges, Table E Pipe Flanges |

Manufacturing Standards / Pressure Rating

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN S31803 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Various Types Of Duplex Steel S31803 Flanges

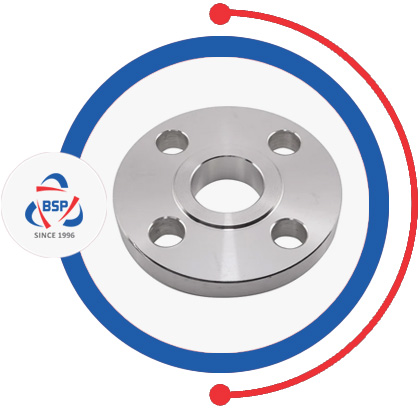

- Duplex Steel S31803 Socket weld Flanges

- 1.4462 Socket weld Flange

- ASTM A182 Duplex Steel S31803 Socket weld Flanges

- Duplex Steel S31803 SWRF Flanges

- UNS S31803 Socket weld Flanges

- ASME SA182 Duplex Steel S31803 SWRF Flanges

- 1.4462 Lap Joint Flange

- UNS S31803 Lap Joint Flanges

- Duplex Steel S31803 Lapped Joint Flanges

- Duplex Steel S31803 LJ Flanges

- ASME SA182 Duplex Steel S31803 Lapped Joint Flanges

- ASTM A182 Duplex Steel S31803 Lap Joint Flanges

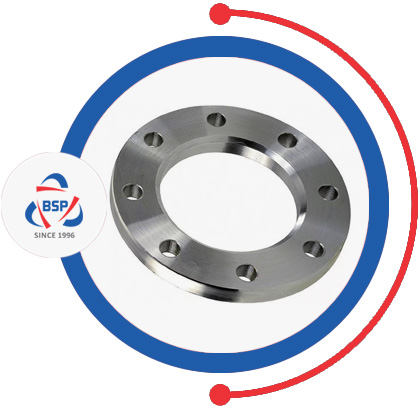

- Duplex Steel S31803 SORF Flanges

- ASTM A182 Duplex Steel S31803 Slip on Flanges

- UNS S31803 Slip on Flanges

- Duplex Steel S31803 Slip on Flanges

- 1.4462 Slip on Flange

- ASME SA182 Duplex Steel S31803 SORF Flanges

- UNS S31803 Forged Flanges

- ASME SA182 Duplex Steel S31803 Forged Flanges

- Duplex Steel S31803 Forged Flanges

- Duplex Steel S31803 Forged Flanges

- 1.4462 Forged Flange

- ASTM A182 Duplex Steel S31803 Forged Flanges

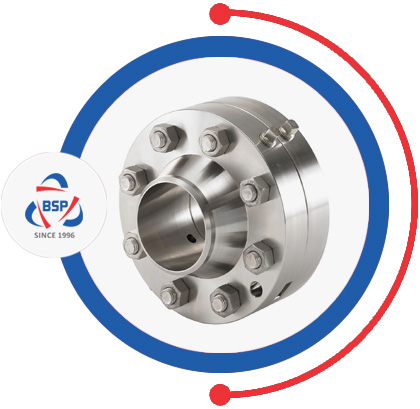

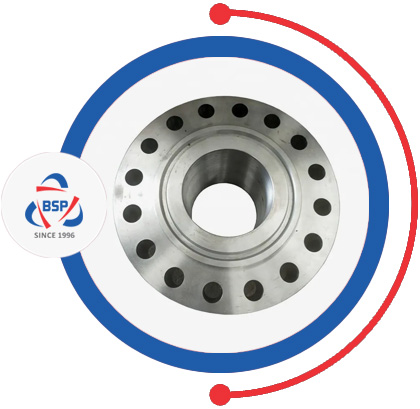

- UNS S31803 Orifice Flanges

- Duplex Steel S31803 Orifice Flanges

- ASTM A182 Duplex Steel S31803 Orifice Flanges

- 1.4462 Orifice Flange

- ASME SA182 Duplex Steel S31803 Orifice Flanges

- Duplex Steel S31803 Orifice Flanges

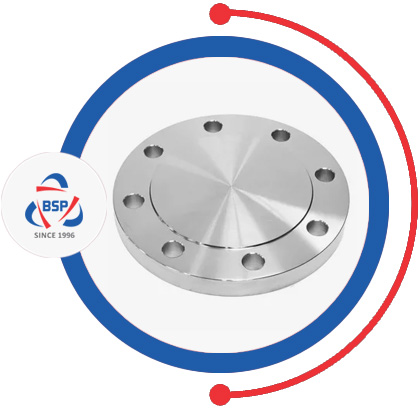

- ASME SA182 Duplex Steel S31803 BLRF Flanges

- Duplex Steel S31803 Blind Flanges

- ASTM A182 Duplex Steel S31803 Blind Flanges

- Duplex Steel S31803 BLRF Flanges

- UNS S31803 Blind Flanges

- 1.4462 Blind Flange

- 1.4462 Welding Neck Flange

- Duplex Steel S31803 Welding Neck Flanges

- Duplex Steel S31803 WNRF Flanges

- ASME SA182 Duplex Steel S31803 WNRF Flanges

- ASTM A182 Duplex Steel S31803 Weld Neck Flanges

- UNS S31803 Weld Neck Flanges

- Duplex Steel S31803 Reducing Flanges

- UNS S31803 Reducing Flanges

- ASME SA182 Duplex Steel S31803 Reducing Flanges

- Duplex Steel S31803 Reducing Flanges

- 1.4462 Reducing Flange

- ASTM A182 Duplex Steel S31803 Reducing Flanges

- Duplex Steel S31803 Threaded Flanges

- 1.4462 Threaded Flange

- UNS S31803 Threaded Flanges

- ASME SA182 Duplex Steel S31803 Screwed Flanges

- Duplex Steel S31803 Screwed Flanges

- ASTM A182 Duplex Steel S31803 Threaded Flanges

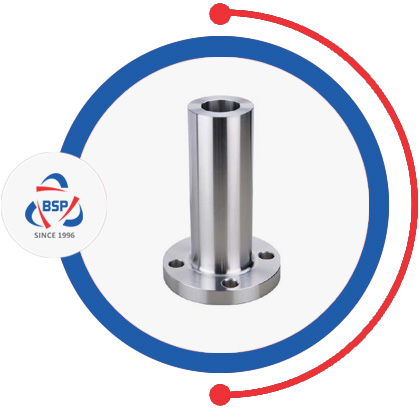

- 1.4462 Long Weld Neck Flange

- Duplex Steel S31803 LWN Flanges

- ASTM A182 Duplex Steel S31803 Long Weld Neck Flanges

- Duplex Steel S31803 Long Weld Neck Flanges

- ASME SA182 Duplex Steel S31803 LWN Flanges

- UNS S31803 Long Weld Neck Flanges

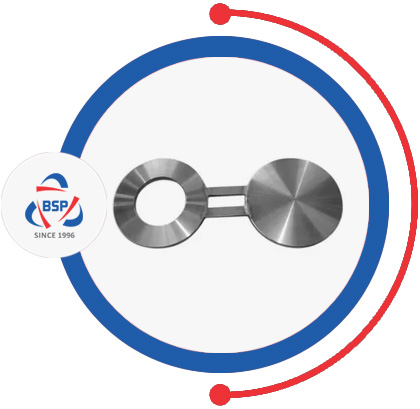

- Duplex Steel S31803 Spectacle Blind Flanges

- ASME SA182 Duplex Steel S31803 Spectacle Blind Flanges

- UNS S31803 Spectacle Blind Flanges

- 1.4462 Spectacle Blind Flange

- ASTM A182 Duplex Steel S31803 Spectacle Blind Flanges

- Duplex Steel S31803 Spectacle Blind Flanges

- ASME SA182 Duplex Steel S31803 RTJ Flanges

- UNS S31803 Ring Type Joint Flanges

- 1.4462 Ring Type Joint Flange

- Duplex Steel S31803 RTJ Flanges

- Duplex Steel S31803 Ring Type Joint Flanges

- ASTM A182 Duplex Steel S31803 RTJ Flanges

Equivalent Grades of Duplex Steel S31803 Flanges

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex Steel S31803 | 1.4462 | S31803 |

View Size Table Of Duplex Steel S31803 Pipe Flanges, We have Global sales network for Duplex Steel S31803 SORF Flanges, Wide Stockist Of Werkstoff No 1.4462 BLRF Flanges, Raised Face, Flat Face Flanges In India.

Check available Sizes of ASME SB 564 Duplex Steel S31803 Pipe Flanges, Ask For Ready Stock of UNS S31803 Male & Female Flanges in Mumbai, India.

BAGODA

Quick ContactSchedule / Class of Duplex Steel S31803 Flanges

| Flange Schedule/Class | Flange Connection Type | Pipe Size – Pipe Flanges | Max. Pressure |

|---|---|---|---|

| ASME B16.5 Class 150 | FNPT | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 1/2″ | 275 psi |

| ASME B16.5 Class 150 | Welded | 1/2″ | 150 psi |

| ASME B16.5 Class 150 | FNPT | 3/4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 3/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 1-1/4″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 1-1/2″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | 2″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 2-1/2″ | 275 psi |

| ASME B16.5 Class 150 | Socket Weld | 3″ | 275 psi |

| ASME B16.5 Class 150 | FNPT | 4″ | 150 psi |

| ASME B16.5 Class 150 | Socket Weld | 4″ | 275 psi |

| ASME B16.5 Class 300 | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1″ | 720 psi |

| ASME B16.5 Class 300 | FNPT | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 1-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 2-1/2″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 3″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 4″ | 720 psi |

| ASME B16.5 Class 300 | Slip On | 4″ | 720 psi |

Pressure Rating Of Duplex Steel S31803 Flanges

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Size Chart Of Duplex Steel S31803 Flange

| Nominal Pipe Size | Outside Diameter of Flanges | Thickness of Flanges | Diameter of Raised Face | Diameter of Hub at Base | Length Thru Hub | Diameter or Bore | Diameter of Hub at Bevel | Radius of Fillet | Depth of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding Neck | Slip-On Threaded Socket | Lap Joint | Slip-on Socket | Lap Joint | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

Weight Chart Of Duplex Steel S31803 Flanges

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub |

Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle |

Diam. of Bolt Holes |

Number of Bolts |

Diam. of Bolts (inch) |

KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

| 1/2" | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2" | 0.4 | 0.9 |

| 3/4" | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2" | 0.7 | 1.5 |

| 1" | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2" | 0.8 | 1.8 |

| 1-1/4" | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2" | 1.2 | 2.6 |

| 1-1/2" | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2" | 1.5 | 3.3 |

| 2" | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8" | 2.3 | 5.1 |

| 2-1/2" | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8" | 3.7 | 8.1 |

| 3" | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8" | 4.1 | 9 |

| 3-1/2" | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8" | 5.1 | 11.2 |

| 4" | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8" | 5.9 | 13 |

| 5" | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4" | 7 | 15.4 |

| 6" | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4" | 8.4 | 18.5 |

| 8" | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4" | 13 | 28.6 |

| 10" | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8" | 18 | 39.5 |

| 12" | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8" | 29 | 64 |

| 14" | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1" | 39 | 86 |

| 16" | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1" | 47 | 103 |

| 18" | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8" | 57 | 126 |

| 20" | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8" | 76 | 167 |

| 24" | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4" | 97 | 214 |

Ready Stock Duplex Steel S31803 Flanges

- ASTM A182 Duplex Steel S31803 SORF Flange

- UNS S31803 Large Diameter Flanges

- Duplex Steel S31803 Paddle Spacer Flanges

- Duplex Steel S31803 JIS B2220 Flange

- UNS S31803 BLRF Flange

- ASTM A182 Duplex Steel S31803 Socket weld Flanges

- ANSI B16.5 Duplex Steel S31803 PN16 Flanges

- Duplex Steel S31803 DIN 2566 PN10 Flanges Stockholder

- Duplex Steel S31803 Square Flanges

- UNS S31803 Blind Flange

- UNS S31803 Slip On Flanges Supplier

- UNS S31803 Flanges

- Duplex Steel S31803 Pipe Flanges

- Duplex Steel S31803 JIS B2220 Flange

- Duplex Steel S31803 Threaded Flanges

- UNS S31803 BLRF Flange

- 6 Inch Duplex Steel S31803 Pipe Flanges

- ASME SA182 Duplex Steel S31803 Forged Flanges

- Class 150 Duplex Steel S31803 Pipe Flange

- ASME SA182 F51 Reducing Flanges

- Duplex Steel S31803 DN150 PN16 Flange

- ASME B16.5 Duplex Steel S31803 Slip on Flanges

- ASME SA182 F51 Screwed Flanges

- Duplex Steel S31803 BS 4504 Flanges

- ASTM A182 F51 Ring Type Joint Flanges

- 3 inch Duplex Steel S31803 Welding Neck 300 LBS Flange

- Duplex Steel S31803 Flanges Manufacturer

- ASTM A182 F51 Blind Flanges Supplier in Mumbai

- ASME B16.5 Duplex Steel S31803 Spectacle Blind Flanges

- Duplex Steel S31803 Loose Flanges

- Duplex Steel S31803 High Hub Blind Flanges

- ASTM A182 F51 Flanges

- Duplex Steel S31803 Lapped Joint Flanges

- ASTM A182 F51 Welding Neck Flanges

- Duplex Steel S31803 Lap Joint Flanges

- ASTM A182 Duplex Steel S31803 Expander Flanges

- Duplex Steel S31803 EN 1092-1 Flange

- Duplex Steel S31803 Raised Face Flanges Exporter

- DIN 1.4462 Pipe Flanges

- ANSI B16.5 Duplex Steel S31803 Male & Female Flanges

- Duplex Steel S31803 BS 4504 Flanges

- ASME SA182 F51 Flat Flanges

- Duplex Steel S31803 AWWA C207 Flange Stockist

- UNS S31803 Orifice Flanges

- S31803 Duplex Steel RTJ Flanges Manufacturer

- Duplex Steel JIS NCF S31803 Class 2500 Flange

- Duplex Steel S31803 JIS B2220 Flange

- ASME SA182 F51 Tongue & Groove Flanges

- Duplex Steel S31803 Long Weld Neck Flanges

- ASTM A182 F51 WNRF Flange

- ASTM A182 Duplex Steel S31803 Plate Flanges

- DIN 1.4462 SWRF Flange

Duplex Steel S31803 Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Duplex S31803 | 0.030 max | 2 max | 1 max | 0.030 max | 0.020 max | 22 - 23 | 3 - 3.50 | 4.50 - 6.50 | 0.14 - 0.20 | Bal |

Duplex Steel S31803 Flanges Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |