UNS K90941 Weldolet, Grade F9 Alloy Threadolet, Alloy Steel F9 Sweepolet Stockist, Alloy Steel F9 Nipple Outlets, CrMo F9 Flexolet, Alloy Steel F9 Branch Outlet Fittings, 1.7386 Latrolet, Chrome Moly F9 Branch Connection Fittings, Alloy Steel F9 Bran Outlet Fittings Supplier in Mumbai, India.

It is an age - hardenable alloy with excessive strength, corrosion-resistance, and exact fabrication characteristics. It is likewise a precipitation - hardenable nickel - chromium alloy containing huge quantities of iron, niobium, and molybdenum at the side of lesser quantities of aluminum and titanium. The age - hardening reaction of the alloy allows annealing and welding in olets without spontaneous hardening at some point of heating and cooling. Alloy Steel F9 Insert weldolet has great rest resistance, and may be fabricated into even the maximum complicated parts. It has great weldability whilst in comparison to the nickel - base superalloys hardened via way of means of aluminum and titanium.

It has exact resistance to oxidation and corrosion at temperatures within the alloy’s useful strength variety in atmospheres encountered in jet engines and fueloline turbine operations. The ease and economic system with which outlet fittings may be fabricated and mixed with exact tensile, fatigue, creep, and rupture strength, have led to its use in a huge variety of applications. Alloy Steel F9 Coupolet is an alloy with a notable aggregate of resistance to oxidation and excessive-temperature strength. It is a nickel - primarily based totally superalloy perfect for fueloline turbine engine, aircraft, business furnace, and chemical processing applications. We have enjoy serving the desires of clients for retailers in various markets such as aerospace, automotive, medical, house - wares, meals service, and lots of others.

Material Specification Chart of Alloy Steel F9 Olets

| Specifications | ASTM A182/ ASME SA182 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Alloy Steel F9 Olets Manufacturing Standards

| ASTM A182/A182M | Wrought Austenitic Alloy Steel F9 Outlet Fittings |

|---|---|

| ASME SA182 – ASTM A182 | Standard Specification for Wrought Austenitic Alloy Steel F9 Outlet Piping Fittings |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

| BS3799 – | Specification for Outlet Fittings for the petroleum industry |

| ASTM A182 – ASME SA182 | Standard Specification for Wrought Austenitic SS Outlet Fittings |

| ASME Standard | ASME/ANSI B16.11, MSS-SP-97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Threaded, Welded, SW, BW |

Various Types Of Alloy Steel F9 Olets

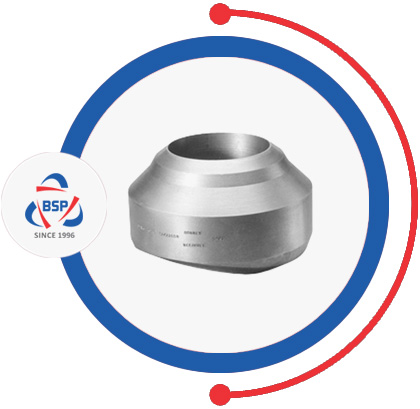

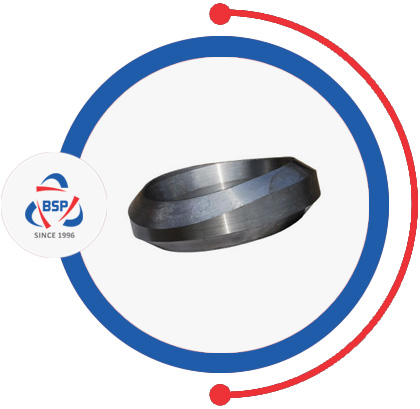

- UNS K90941 Weldolet

- Grade F9 Alloy Weldolet

- Cr-Mo A182 F9 Weldolet

- Alloy Steel F9 Welding Outlet

- 1.7386 Welding Outlet

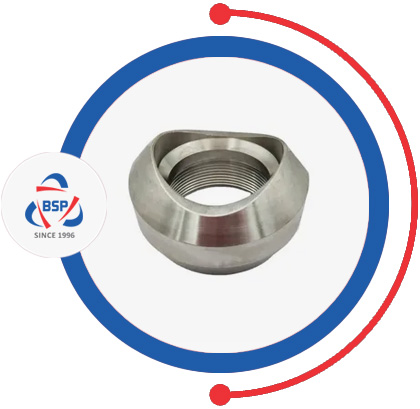

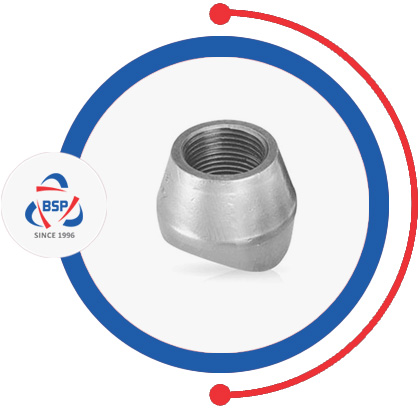

- Alloy Steel F9 Threadolet

- 1.7386 Threadolet

- UNS K90941 Threaded Outlet

- Chrome Moly F9 Threading Outlet

- Alloy Steel F9 Threadolet

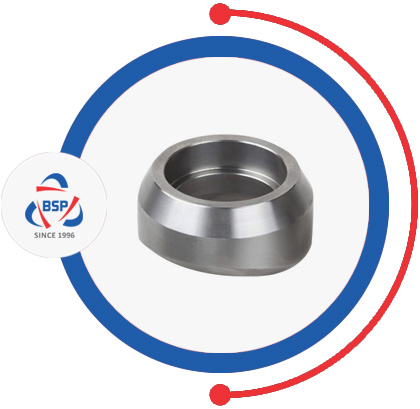

- Alloy Steel F9 Socket Weld Olets

- F9 Alloy Steel Sockolet

- UNS K90941 Sockolet

- 1.7386 Sockolet

- CrMo F9 Socket Weld Outlets

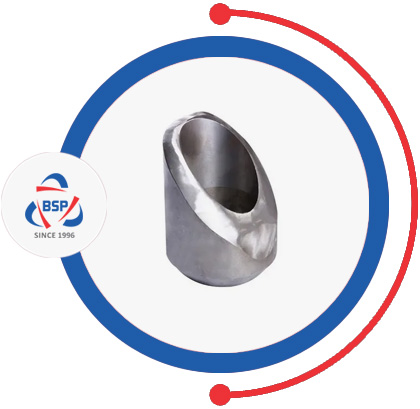

- Chrome Moly F9 Elbow Outlets

- Alloy Steel F9 Elbolet

- 1.7386 Elbolet

- UNS K90941 Elbolet

- Alloy Steel F9 Latrolet

- UNS K90941 Latrolet

- F9 Alloy Steel Lateral Outlet

- 1.7386 Latrolet

- Cr-Mo A182 F9 Nipple Outlets

- UNS K90941 Nippolet

- 1.7386 Nippolet

- Alloy Steel F9 Nippolet

- 1.7386 Flexolet

- Chrome Moly F9 Flexolet

- UNS K90941 Flexolet

- Alloy Steel F9 Flexolet

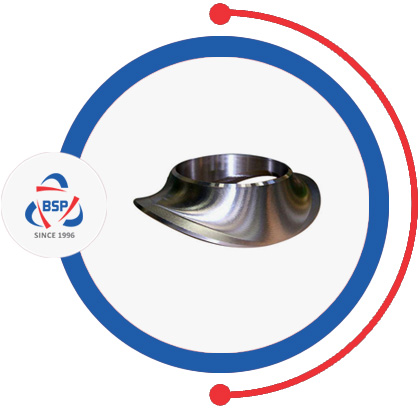

- 1.7386 Sweepolet

- Alloy Steel F9 Swept Outlet

- Grade F9 Alloy Sweepolet

- UNS K90941 Sweepolet

- F9 CrMo Brazolet

- 1.7386 Brazolet

- Alloy Steel F9 Brazolet

- UNS K90941 Brazolet

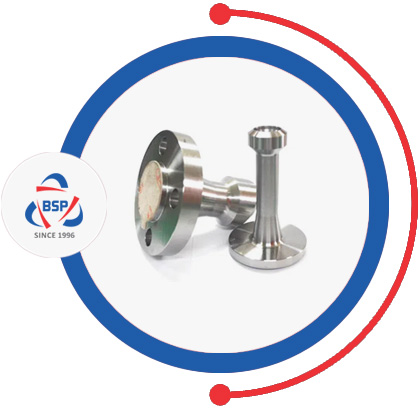

- CrMo F9 Flangeolet

- Alloy Steel F9 Flangeolet

- UNS K90941 Flangeolet

- 1.7386 Flangeolet

- UNS K90941 Coupolet

- 1.7386 Coupolet

- Alloy Steel F9 Coupolet

- Cr-Mo A182 F9 Coupolet

- Chrome Moly F9 Insert Weld Outlet

- UNS K90941 Insert Weld Outlet

- Alloy Steel F9 Insert Weld Outlet

- 1.7386 Insert Weld Outlet

Equivalent Grades of Alloy Steel F9 Insert Weld Outlet

- 5" Nb Grade F9 Alloy Elbolet

- F9 Alloy Steel Industrial Olets

- F9 Alloy Steel4 Branch Connection

- CrMo F9 Olets Manufacturer

- CrMo F9 Olet Fittings

- Chrome Moly F9 Outlet Fittings

- F9 CrMo Welding Outlets

- UNS K90941 Olet Fittings

- Cr-Mo A182 F9 Branch Outlets Fittings

- Chrome Moly F9 Flangeolet

- Alloy Steel Fl Coupling Outlet

- ASTM A182 Alloy Steel F9 Flexible Outlet

- F9 Alloy Steel Sweepolet

- ASTM A182 Alloy Steel F9 Flexolet

- F9 CrMo Outlets

- Alloy Steel F9 Olet Fittings

- F9 Alloy Steel Sockolet

- ASTM A182 Alloy Steel F9 Olets Branch Fittings

- Alloy Steel F9 Coupolet

- Alloy Steel F9 Olets

- F9 Alloy Steel Nipple Outlet Exporter

- DIN 1.7386 Socket Weld Outlets

- Grade F9 Alloy Insertweldolet

- ASME SA182 Alloy Steel F9 Threadolet

- Cr-Mo A182 F9 Brazolet Supplier in Mumbai

- CrMo F9 Latrolet

- Alloy Steel F9 Nippolet

- Alloy Steel F9 Insert Welding Outlet Manufacturer

- Alloy Steel F9 Threading Outlet

- Alloy Steel F9 Weldolet Distributor

- F9 Alloy Steel Threading Outlet

- F9 Alloy Stee Pipe Outlets

| STANDARD | WERKSTOFF NR. | UNS | EN | DIN |

| A182 F9 | 1.7386 | K90941 | 9Cr-1Mo | X 12 CrMo 9 1 |

View Thickness Table Of Alloy Steel F9 Olets, We have Global sales network for Grade F9 Alloy Outlet Connection Fittings, Wide Stockist Of Werkstoff No 1.7386 Socket Weld Outlets In India.

Check available Sizes of ASME SA 182 Alloy Steel F9 Branch Outlets Fittings, Ask For Ready Stock of UNS K90941 Threadolets in Mumbai, India.

BAGODA

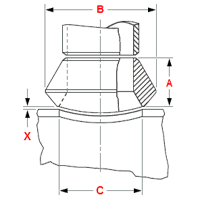

Quick ContactAlloy Steel F9 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Alloy Steel F9 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Alloy Steel F9 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F9 Nipolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F9 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Alloy Steel F9 Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Ready Stock Alloy Steel F9 Olets

Alloy Steel F9 Olets Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.5 - 1 | 0.03 | 0.03 | 8 - 10 | 0.9 - 1.1 |

Alloy Steel F9 Olets Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| A182 F9 | 380 | 585 | 20 |