UNS N10665 Weldolet, Hastelloy® Alloy B-2 Branch Outlet Fittings, Hastelloy B2 Flexolet, Hastelloy Alloy B-2 Branch Connection Fittings, Hastelloy B-2 Sweepolet Stockist, Hastelloy B2 Threadolet, 2.4617 Latrolet, Nickel Alloy B2 Nipple Outlets, Hastelloy B2 Outlet Fittings Supplier in Mumbai, India.

It is particularly nicely perfect to forming components with the aid of using spinning, wherein it can possibly additionally be utilized in oxidizing environments that reason the formation of a passive film. Hastelloy Alloy WNR 2.4617 Nipple Outle is generally used within the chemical, marine, scientific and paper manufacturing industries for objects which include scrapers, together with pump shafts, oil - nicely tools, springs, marine propeller shafts, etc. For Pump shafts for fire-combating pumps, it's miles frequently utilized in high strength (ensuing in smaller diameter shafts) and resistance to flowing seawater. It gives wonderful corrosion resistance in quite number of environments together with sea water, hydrofluoric acid, sulfuric acid and alkalis.

Resistance to hydrogen sulfide makes these olets beneficial in sour - fueloline environments making it extraordinarily famous within the oil patch. The mixture of very low corrosion fees in high-speed sea water and high strength make our outlets specifically appropriate for shafts of centrifugal pumps in marine service. Nickel Alloy B2 Brazolet has corrosion resistance in an intensive variety of marine and chemical environments, from natural water to non - oxidizing mineral acids, salts and alkalis. It combines the wonderful corrosion resistance function with the introduced benefits of greater strength and hardness. It is an alloy (i.e. mixture of extra factors of which at the least one is a metal, and wherein the resultant material has metallic properties).

Material Specification Chart of Hastelloy B2 Olets

| Specifications | ASTM B366/ ASME SB366 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Hastelloy B2 Olets Manufacturing Standards

| ASTM B366/B366 | Wrought Austenitic Hastelloy B2 Outlet Fittings |

|---|---|

| ASME SB366 – ASTM B366 | Standard Specification for Wrought Austenitic Hastelloy B2 Outlet Piping Fittings |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

| BS3799 – | Specification for Outlet Fittings for the petroleum industry |

| ASTM B366 – ASME SB366 | Standard Specification for Wrought Austenitic SS Outlet Fittings |

| ASME Standard | ASME/ANSI B16.11, MSS-SP-97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Threaded, Welded, SW, BW |

Various Types Of Hastelloy B2 Olets

- Hastelloy B2 Weldolet

- Hastelloy B-2 Welding Outlet

- Hastelloy Alloy B-2 Weldolet

- 2.4617 Welding Outlet

- UNS N10665 Weldolet

- Hastelloy Alloy B-2 Threadolet

- 2.4617 Threadolet

- UNS N10665 Threaded Outlet

- Nickel Alloy B-2 Threadolet

- Hastelloy® Alloy B2 Threading Outlet

- Hastelloy B2 Socket Weld Olets

- Hastelloy B-2 Sockolet

- UNS N10665 Sockolet

- Hastelloy Alloy B-2 Socket Weld Outlets

- 2.4617 Sockolet

- Hastelloy B-2 Elbolet

- Hastelloy® Alloy B2 Elbow Outlets

- UNS N10665 Elbolet

- 2.4617 Elbolet

- Hastelloy Alloy B-2 Lateral Outlet

- Hastelloy B2 Latrolet

- 2.4617 Latrolet

- UNS N10665 Latrolet

- Hastelloy B-2 Nippolet

- UNS N10665 Nippolet

- 2.4617 Nippolet

- Hastelloy® Alloy B2 Nipple Outlets

- Hastelloy Alloy B-2 Flexolet

- 2.4617 Flexolet

- UNS N10665 Flexolet

- Hastelloy B2 Flexolet

- 2.4617 Sweepolet

- Hastelloy® Alloy B-2 Sweepolet

- Hastelloy B2 Swept Outlet

- UNS N10665 Sweepolet

- Hastelloy Alloy B2 Brazolet

- Hastelloy B-2 Brazolet

- UNS N10665 Brazolet

- 2.4617 Brazolet

- Hastelloy B-2 Flangeolet

- UNS N10665 Flangeolet

- Hastelloy® Alloy B2 Flangeolet

- 2.4617 Flangeolet

- Hastelloy Alloy B-2 Coupolet

- 2.4617 Coupolet

- Hastelloy B2 Coupolet

- UNS N10665 Coupolet

- Hastelloy® Alloy B2 Insert Weld Outlet

- UNS N10665 Insert Weld Outlet

- Hastelloy B-2 Insert Weld Outlet

- 2.4617 Insert Weld Outlet

Equivalent Grades of Hastelloy B2 Olets

| STANDARD | WERKSTOFF NR. | UNS |

| Hastelloy B2 | 2.4617 | N10665 |

View Thickness Table Of Hastelloy B2 Olets, We have Global sales network for Hastelloy B2 Outlet Connection Fittings, Wide Stockist Of Werkstoff No 2.4617 Socket Weld Outlets In India.

Check available Sizes of ASME SB366 Hastelloy B2 Branch Outlets Fittings, Ask For Ready Stock of UNS N10665 Threadolets in Mumbai, India.

BAGODA

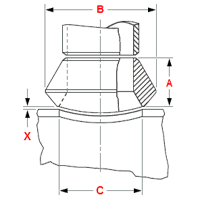

Quick ContactHastelloy B2 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Hastelloy B2 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Hastelloy B2 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Hastelloy B2 Nipolet Dimensions

Hastelloy B2| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Hastelloy B2 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Hastelloy B2 Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Ready Stock Hastelloy B2 Olets

- Hastelloy B2 Welding Outlets

- Hastelloy Alloy B-2 Threading Outlet

- Hastelloy B2 Sweepolet

- Nickel Alloy B-2 Industrial Olets

- Hastelloy B2 Insert Welding Outlet Manufacturer

- Hastelloy Alloy B-2 Outlet Fittings

- Nickel Alloy B2 Branch Connection

- Hastelloy B-2 Olets

- 5" Nb Hastelloy B2 Elbolet

- Hastelloy Alloy B2 Pipe Outlets

- Hastelloy Alloy B-2 Nippolet

- Hastello B2 Olet Fittings

- Hastelloy B-2 Outlets

- UNS N10665 Olet Fittings

- ASTM B366 Hastelloy B2 Flexible Outlet

- Hastelloy B2 Latrolet

- Hastelloy B-2 Flangeolet

- ASME SB366 Hastelloy B2 Threadolet

- Nickel Alloy B-2 Coupling Outlet

- Hastelloy® Alloy B2 Nipple Outlet Exporter

- DIN 2.4617 Socket Weld Outlets

- Hastelloy B-2 Olet Fittings

- Hastelloy Alloy B2 Threading Outlet

- Hastelloy B2 Brazolet Supplier in Mumbai

- Hastelloy® Alloy B-2 Sockolet

- ASTM B366 Hastelloy Olets Branch Fittings

- Hastelloy B-2 Branch Outlets Fittings

- Hastelloy B2 Olets Manufacturer

- Hastelloy B-2 Weldolet Distributor

- ASTM B366 Hastelloy B2 Flexolet

- Hastelloy B-2 Insertweldolet

- Hastelloy B2 Coupolet

Hastelloy B2 Olets Chemical Composition

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| Hastelloy B2 | 0.02 max | 1.0 max | 0.1 max | 0.03 max | 1.0 max | Bal | 1.0 max | 2.0 max | 26 – 30 | 0.04 max |

Hastelloy B2 Olets Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy B2 | 9.2 g/cm3 | 1370 °C (2500 ºF ) | Psi – 1,10,000 , MPa – 760 | Psi – 51000 , MPa – 350 | 40 % |