2.4360 Latrolet, Monel 400 Branch Outlet Fittings, Monel® Alloy 400 Threadolet, Nickel Alloy 400 Nipple Outlets, UNS N04400 Weldolet, Monel 400 Flexolet, Monel 400 Sweepolet Stockist, Alloy 400 Branch Connection Fittings, Monel Alloy 400 Outlet Fittings Supplier in Mumbai, India.

It has applications in piping structures, warmness exchanges, bleaching structures and pollutants manipulate equipment. Monel Alloy WNR 2.4361 Insert weldolet also are used substantially within the chemical system enterprise which includes the manufacturing of phosphate-primarily based totally fertilizers. Most not unusual fusion and resistance techniques can be employed, wherein for optimum corrosion resistance; it's far advocated to apply filler metals of identical or better alloy content. It has superb resistance to pitting corrosion, strain corrosion cracking and a miles higher resistance to crevice corrosion than different steels of alloy. It is ferrite metal formulated for number one forming into wrought products.

It is excessive chromium and non-hardenable metal with great corrosion resistance. They are referred to as excessive-alloy steels that have great corrosion resistance in assessment with different steels as they comprise extra chromium. It is regularly utilized in boiler baffles, tube bases, furnace parts, and oil burner parts, kiln linings, annealing boxes, business mufflers and glass molds. Nickel Alloy 400 Coupolet has super resistance to decreasing sulfurous gases, in addition to superb resistance to oxidation in air. It is a completely excessive give up austenitic metal, that's designed with a mixture of effect durability resistance to chloride strain corrosion cracking, and pitting and crevice corrosion with strength. It is firstly advanced to be used in seawater and different competitive chloride-bearing environments.

Material Specification Chart of Monel 400 Olets

| Specifications | ASTM B366/ ASME SB366 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Monel 400 Olets Manufacturing Standards

| ASTM B366/B366 | Wrought Austenitic Monel 400 Outlet Fittings |

|---|---|

| ASME SB366 – ASTM B366 | Standard Specification for Wrought Austenitic Monel 400 Outlet Piping Fittings |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

| BS3799 – | Specification for Outlet Fittings for the petroleum industry |

| ASTM B366 – ASME SB366 | Standard Specification for Wrought Austenitic SS Outlet Fittings |

| ASME Standard | ASME/ANSI B16.11, MSS-SP-97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Threaded, Welded, SW, BW |

Various Types Of Monel 400 Olets

- 2.4360 Welding Outlet

- Monel 400 Welding Outlet

- Monel Alloy 400 Weldolet

- Alloy 400 Weldolet

- UNS N04400 Weldolet

- Nickel Alloy 400 Threadolet

- UNS N04400 Threaded Outlet

- 2.4360 Threadolet

- Monel Alloy 400 Threadolet

- Monel 400 Threading Outlet

- Monel Alloy 400 Socket Weld Outlets

- 2.4360 Sockolet

- Alloy 400 Sockolet

- UNS N04400 Sockolet

- Monel 400 Socket Weld Olets

- UNS N04400 Elbolet

- Nickel Alloy 400 Elbow Outlets

- Alloy 400 Elbolet

- 2.4360 Elbolet

- 2.4360 Latrolet

- UNS N04400 Latrolet

- Alloy 400 Latrolet

- Monel Alloy 400 Lateral Outlet

- UNS N04400 Nippolet

- 2.4360 Nippolet

- Nickel Alloy 400 Nipple Outlets

- Alloy 400 Nippolet

- Alloy 400 Flexolet

- Monel Alloy 400 Flexolet

- 2.4360 Flexolet

- UNS N04400 Flexolet

- Nickel Alloy 400 Sweepolet

- Monel 400 Swept Outlet

- 2.4360 Sweepolet

- UNS N04400 Sweepolet

- Monel Alloy 400 Brazolet

- Alloy 400 Brazolet

- 2.4360 Brazolet

- UNS N04400 Brazolet

- 2.4360 Flangeolet

- Alloy 400 Flangeolet

- UNS N04400 Flangeolet

- Nickel Alloy 400 Flangeolet

- Monel Alloy 400 Coupolet

- Alloy 400 Coupolet

- 2.4360 Coupolet

- UNS N04400 Coupolet

- 2.4360 Insert Weld Outlet

- Nickel Alloy 400 Insert Weld Outlet

- Alloy 400 Insert Weld Outlet

- UNS N04400 Insert Weld Outlet

Equivalent Grades of Monel 400 Olets

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

| Monel 400 | N04400 | 2.4360 | NU-30M | NiCu30Fe | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 |

View Thickness Table Of Monel 400 Olets, We have Global sales network for Monel 400 Outlet Connection Fittings, Wide Stockist Of Werkstoff No 2.4360 Socket Weld Outlets In India.

Check available Sizes of ASME SB366 Monel 400 Branch Outlets Fittings, Ask For Ready Stock of UNS N04400 Threadolets in Mumbai, India.

BAGODA

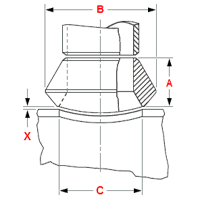

Quick ContactMonel 400 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Monel 400 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Monel 400 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Monel 400 Nipolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Monel 400 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Monel 400 Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Ready Stock Monel 400 Olets

- Monel 400 Weldolet Distributor

- Alloy 400 Insert Welding Outlet Manufacturer

- Monel 400 Olet Fittings

- Monel 400 Coupolet

- Nickel Alloy 400 Sockolet

- Monel® Alloy 400 Nipple Outlet Exporter

- 5" Nb Monel 400 Elbolet

- Monel Alloy 400 Industrial Olets

- Monel Alloy 400 Olets Manufacturer

- Monel Alloy 400 Threading Outlet

- Monel 400 Olets

- ASME SB366 Monel 400 Threadolet

- Monel Alloy 400 Flangeolet

- Monel 400 Olet Fittings

- Nickel Alloy 400 Coupling Outlet

- Monel 400 Sweepolet

- Monel 400 Branch Outlets Fittings

- Monel Alloy 400 Outlet Fittings

- ASTM B366 Monel 400 Flexible Outlet

- ASTM B366 Monel Olets Branch Fittings

- DIN 2.4360 Socket Weld Outlets

- Nickel Alloy 400 Branch Connection

- Alloy 400 Outlets

- Monel® Alloy 400 Threading Outlet

- Monel Alloy 400 Pipe Outlets

- Alloy 400 Brazolet Supplier in Mumbai

- Monel 400 Insertweldolet

- Nickel Alloy 400 Nippolet

- UNS N04400 Olet Fittings

- ASTM B366 Monel 400 Flexolet

- Monel 400 Latrolet

- Monel 400 Welding Outlets

Monel 400 Olets Chemical Composition

| Grade | Ni | C | Al | Mn | Si | Fe | Cu | S |

| Monel 400 | 63.0 min | 0.3 max | 0.50 max | 2.0 max | 0.5 max | 1.0 - 2.5 | 28.0 - 34.0 | 0.02 max |

Monel 400 Olets Mechanical Properties

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 35,000 , MPa – 240 | Psi – 80,000 , MPa – 550 | 40 % |