Titanium Gr 2 Sweepolet Stockist, Alloy Titanium Branch Connection Fittings, UNS R50400 Weldolet, 3.7035 Latrolet, Titanium Gr 2 Branch Outlet Fittings, Ti Gr 2 Threadolet, Titanium Gr 2 Flexolet, Titanium Alloy Gr 2 Nipple Outlets, Titanium Gr 2 Outlet Fittings Supplier in Mumbai, India.

The titanium addition reduces or prevents carbide precipitation at some stage in welding and in 800 Degree F – 1500 Degree F service. Titanium is introduced to the composition of these olets to suppress grain boundary chromium carbide precipitation and decrease susceptibility to intergranular corrosion. These titanium bearing are stabilized towards carbide precipitation and designed for operation inside the harmful temperature variety in which carbide precipitation develops. Ti-Alloy Gr 2 Nipple Outlet are ordinary via way of means of customers in numerous spheres of the industries starting from primary industries which includes Sugar, Paper, Textile, Dairy, Engineering, etc. They also are utilized in extra complicated which includes Oil & Gas, Petrochemical, Chemical & Fertilizers, Power Generation and Nuclear Industries.

It is truly a better chromium, nickel and molybdenum model of stainless designed mainly for increased strength and corrosion resistance. It is mostly constituted of chromium and nickel together with hint quantities of carbon, phosphorus, sulfur, silicon and balanced with iron. Due to the molybdenum content, they may be extra proof against widespread corrosion and pitting/crevice corrosion. Titanium UNS R50400 Brazolet is regularly utilized in chemical processing, oil refineries, meals processing, paper mills, photographic handling, marine applications and fueloline scrubbers. It is truly a low carbon model of grade, and has the equal high strength and corrosion resistance as metal however can produce more potent welds because of the low carbon content.

Material Specification Chart of Titanium Gr 2 Olets

| Specifications | ASTM B363/ ASME SB363 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Titanium Gr 2 Olets Manufacturing Standards

| ASTM B363/B363 | Wrought Austenitic Titanium Gr 2 Outlet Fittings |

|---|---|

| ASME SB363 – ASTM B363 | Standard Specification for Wrought Austenitic Titanium Gr 2 Outlet Piping Fittings |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

| BS3799 – | Specification for Outlet Fittings for the petroleum industry |

| ASTM B363 – ASME SB363 | Standard Specification for Wrought Austenitic SS Outlet Fittings |

| ASME Standard | ASME/ANSI B16.11, MSS-SP-97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Threaded, Welded, SW, BW |

Various Types Of Titanium Gr 2 Olets

- Alloy Titanium Welding Outlet

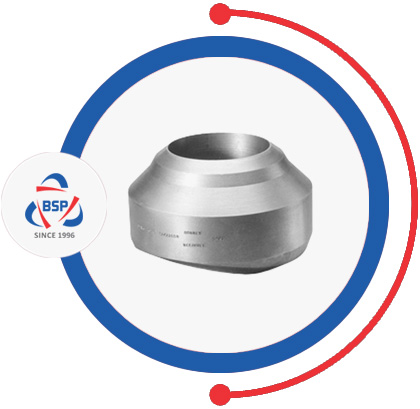

- UNS R50400 Weldolet

- 3.7035 Welding Outlet

- Titanium Gr 2 Weldolet

- Ti Alloy Grade 2 Weldolet

- Titanium Threading Outlet

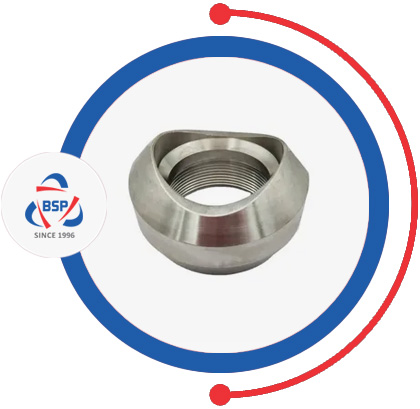

- Ti Alloy Grade 2 Threadolet

- 3.7035 Threadolet

- Ti Gr 2 Threadolet

- UNS R50400 Threaded Outlet

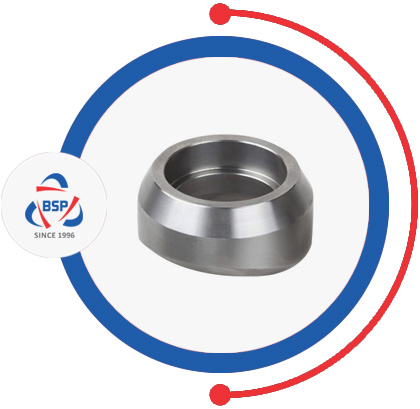

- UNS R50400 Sockolet

- Alloy Titanium Socket Weld Outlets

- Titanium Gr 2 Socket Weld Olets

- Ti Gr 2 Sockolet

- 3.7035 Sockolet

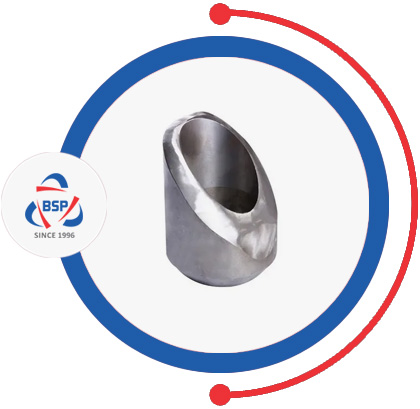

- UNS R50400 Elbolet

- Titanium Gr 2 Elbolet

- Ti Gr 2 Elbow Outlets

- 3.7035 Elbolet

- UNS R50400 Latrolet

- Titanium Gr 2 Latrolet

- 3.7035 Latrolet

- Grade 2 Titanium Lateral Outlet

- Alloy Titanium Nipple Outlets

- Titanium Gr 2 Nippolet

- 3.7035 Nippolet

- UNS R50400 Nippolet

- 3.7035 Flexolet

- Titanium Alloy Gr 2 Flexolet

- UNS R50400 Flexolet

- >Titanium Gr 2 Flexolet

- 3.7035 Sweepolet

- Titanium Gr 2 Swept Outlet

- Ti Gr 2 Sweepolet

- UNS R50400 Sweepolet

- Titanium Gr 2 Brazolet

- Ti Alloy Grade 2 Brazolet

- 3.7035 Brazolet

- UNS R50400 Brazolet

- Grade 2 Titanium Flangeolet

- UNS R50400 Flangeolet

- Titanium Gr 2 Flangeolet

- 3.7035 Flangeolet

- Titanium Gr 2 Coupolet

- 3.7035 Coupolet

- Alloy Titanium Coupolet

- UNS R50400 Coupolet

- UNS R50400 Insert Weld Outlet

- Titanium Gr 2 Insert Weld Outlet

- Ti Alloy Grade 2 Insert Weld Outlet

- 3.7035 Insert Weld Outlet

Equivalent Grades of Titanium Gr 2 Olets

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr 2 | 3.7035 | R50400 |

View Thickness Table Of Titanium Gr 2 Olets, We have Global sales network for Titanium Gr 2 Outlet Connection Fittings, Wide Stockist Of Werkstoff No 3.7035 Socket Weld Outlets In India.

Check available Sizes of ASME SB363 Titanium Gr 2 Branch Outlets Fittings, Ask For Ready Stock of UNS R50400 Threadolets in Mumbai, India.

BAGODA

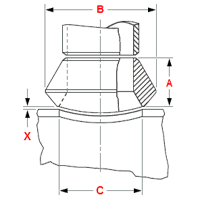

Quick ContactTitanium Gr 2 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Titanium Gr 2 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Titanium Gr 2 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Titanium Gr 2 Nipolet Dimensions

Titanium Gr 2| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Titanium Gr 2 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Titanium Gr 2 Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Ready Stock Titanium Gr 2 Olets

- Titanium Gr 2 Sockolet

- Titanium Gr 2 Insertweldolet

- ASME SB363 Titanium Gr 2 Threadolet

- Titanium Gr 2 Threading Outlet

- Titanium Olets

- Ti Gr 2 Nipple Outlet Exporter

- Titanium Gr 2 Insert Welding Outlet Manufacturer

- ASTM B363 Titanium Olets Branch Fittings

- Titanium Gr 2 Coupolet

- Ti Gr 2 Industrial Olets

- Titanium Gr 2 Olet Fittings

- Grade 2 Titanium Outlet Fittings

- Titanium Gr 2 Welding Outlets

- Titanium Gr 2 Branch Outlets Fittings

- Titanium Gr 2 Outlets

- Titanium Gr 2 Weldolet Distributor

- Ti Alloy Grade 2 Pipe Outlets

- DIN 3.7035 Socket Weld Outlets

- Titanium Gr 2 Threading Outlet

- Titanium Gr 2 Olet Fittings

- Titanium Gr 2 Latrolet

- Titanium Gr 2 Coupling Outlet

- Grade 2 Titanium Olets Manufacturer

- Alloy Titanium Flangeolet

- Titanium Sweepolet

- Titanium Alloy Gr 2 Brazolet Supplier in Mumbai

- ASTM B363 Titanium Gr 2 Flexible Outlet

- ASTM B363 Titanium Gr 2 Flexolet

- 5" Nb Titanium Gr 2 Elbolet

- UNS R50400 Olet Fittings

- Titanium Alloy Gr 2 Nippolet

- Ti Alloy Grade 2 Branch Connection

Titanium Gr 2 Olets Chemical Composition

| Element | Ti | C | Fe | H | N | O |

| Titanium Gr 2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max |

Titanium Gr 2 Olets Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Ti Gr 2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |