2.4856 Latrolet, Nickel Alloy 625 Nipple Outlets, Inconel 625 Branch Outlet Fittings, Inconel 625 Flexolet, Inconel 625 Sweepolet Stockist, Monel Alloy 625 Threadolet, UNS N06625 Weldolet, Alloy 625 Branch Connection Fittings, Monel Alloy 625 Outlet Fittings Supplier in Mumbai, India.

It combines the corrosion resistance however offers the introduced gain of extra strength and hardness (because of its age hardening ability). The increased properties are acquired through including aluminum and titanium to the nickel - copper products, and through heating beneath managed situations in order that submicroscopic debris are brought on throughout the direction of the matrix. Inconel Alloy WNR 2.4856 Insertweldolet is used for pump shafts, health practitioner blades and scrapers, oil - nicely gear and instruments, springs, valve trim, fasteners, and marine propeller shafts.

For propeller shafts, it's miles used for excessive strength (ensuing in smaller diameter shafts and for that reason smaller bearing) and resistance to seawater. Low corrosion prices in sea water make our shops appropriate for marine provider even though pitting can also additionally arise in stagnant waters however the charge of pitting slows after preliminary attack. Nickel Alloy 625 Coupolet is non - magnetic and must be annealed whilst welded and the weldment then pressure relieved earlier than aging. However, it's miles feasible to expand a magnetic layer at the floor of our outlet fittings throughout processing. Electrical resistivity is markedly having an effect on through thermal records due to the age - hardening traits of these products.Material Specification Chart of Inconel 625 Olets

| Specifications | ASTM B366/ ASME SB366 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Inconel 625 Olets Manufacturing Standards

| ASTM B366/B366 | Wrought Austenitic Inconel 625 Outlet Fittings |

|---|---|

| ASME SB366 – ASTM B366 | Standard Specification for Wrought Austenitic Inconel 625 Outlet Piping Fittings |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

| BS3799 – | Specification for Outlet Fittings for the petroleum industry |

| ASTM B366 – ASME SB366 | Standard Specification for Wrought Austenitic SS Outlet Fittings |

| ASME Standard | ASME/ANSI B16.11, MSS-SP-97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Threaded, Welded, SW, BW |

Various Types Of Inconel 625 Olets

- 2.4856 Welding Outlet

- UNS N06625 Weldolet

- Inconel 625 Welding Outlet

- Inconel Alloy 625 Weldolet

- Alloy 625 Weldolet

- Inconel Alloy 625 Threadolet

- Inconel 625 Threading Outlet

- Nickel Alloy 625 Threadolet

- 2.4856 Threadolet

- UNS N06625 Threaded Outlet

- UNS N06625 Sockolet

- Inconel Alloy 625 Socket Weld Outlets

- 2.4856 Sockolet

- Alloy 625 Sockolet

- Inconel 625 Socket Weld Olets

- 2.4856 Elbolet

- Inconel 625 Elbolet

- UNS N06625 Elbolet

- Nickel Alloy 625 Elbow Outlets

- UNS N06625 Latrolet

- 2.4856 Latrolet

- Alloy 625 Latrolet

- Inconel Alloy 625 Lateral Outlet

- Alloy 625 Nippolet

- Nickel Alloy 625 Nipple Outlets

- 2.4856 Nippolet

- UNS N06625 Nippolet

- 2.4856 Flexolet

- Inconel Alloy 625 Flexolet

- UNS N06625 Flexolet

- Alloy 625 Flexolet

- Nickel Alloy 625 Sweepolet

- UNS N06625 Sweepolet

- 2.4856 Sweepolet

- Inconel 625 Swept Outlet

- UNS N06625 Brazolet

- Inconel Alloy 625 Brazolet

- Alloy 625 Brazolet

- 2.4856 Brazolet

- Nickel Alloy 625 Flangeolet

- UNS N06625 Flangeolet

- 2.4856 Flangeolet

- Alloy 625 Flangeolet

- UNS N06625 Coupolet

- Alloy 625 Coupolet

- Inconel Alloy K500 Coupolet

- 2.4856 Coupolet

- 2.4856 Insert Weld Outlet

- Alloy 625 Insert Weld Outlet

- UNS N06625 Insert Weld Outlet

- Nickel Alloy 625 Insert Weld Outlet

Equivalent Grades of Inconel 625 Olets

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | AFNOR | GOST | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | NC22DNB4M | ХН75МБТЮ | NiCr22Mo9Nb |

View Thickness Table Of Inconel 625 Olets, We have Global sales network for Inconel 625 Outlet Connection Fittings, Wide Stockist Of Werkstoff No 2.4856 Socket Weld Outlets In India.

Check available Sizes of ASME SB366 Inconel 625 Branch Outlets Fittings, Ask For Ready Stock of UNS N06625 Threadolets in Mumbai, India.

BAGODA

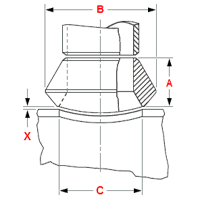

Quick ContactInconel 625 Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Inconel 625 Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Inconel 625 Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Inconel 625 Nipolet Dimensions

Inconel 625| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Inconel 625 Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Inconel 625 Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Ready Stock Inconel 625 Olets

- Inconel Alloy 625 Threading Outlet

- Inconel 625 Welding Outlets

- Inconel 625 Sweepolet

- Inconel Alloy 625 Nipple Outlet Exporter

- ASTM B366 Inconel Olets Branch Fittings

- Inconle Alloy 625 Industrial Olets

- ASTM B366 Inconel 625 Flexolet

- Inconel Alloy 625 Flangeolet

- Inconel 625 Olet Fittings

- Inconel Alloy 625 Pipe Outlets

- 5" Nb Inconel 625 Elbolet

- ASME SB366 Inconel 625 Threadolet

- Inconel Alloy 625 Threading Outlet

- UNS N06625 Olet Fittings

- Alloy 625 Outlets

- DIN 2.4856 Socket Weld Outlets

- Nickel Alloy 625 Nippolet

- Inconel 625 Coupolet

- Nickel Alloy 625 Branch Connection

- Inconel 625 Latrolet

- ASTM B366 Inconel 625 Flexible Outlet

- Nickel Alloy 625 Sockolet

- Inconel Alloy 625 Olets Manufacturer

- Inconel 625 Branch Outlets Fittings

- Inconel 625 Weldolet Distributor

- Alloy 625 Insert Welding Outlet Manufacturer

- Inconel 625 Olet Fittings

- Inconel 625 Insertweldolet

- Alloy 625 Brazolet Supplier in Mumbai

- Inconel 625 Olets

- Nickel Alloy 625 Coupling Outlet

- Inconel Alloy 625 Outlet Fittings

Monel 625 Olets Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | - | 5.0 max | 58.0 min | 20.0 - 23.0 |

Inconel 625 Olets Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |