Stainless Steel 317L Flexolet, 317L Stainless Steel Nipple Outlets, SS 317L Sweepolet Stockist, UNS S31703 Weldolet, SS 317L Branch Connection Fittings, 1.4438 Latrolet, SS 317L Branch Outlet Fittings, Stainless Steel 317L Threadolet, 317L SS Outlet Fittings Supplier in Mumbai, India.

For answer annealing, sluggish managed cooling from 1500 Degree F / 1600 Degree F, and for hardening, warmth as much as 1700 Degree F / 1850 Degree F, in addition quench in air or oil. While these outlet fittings may be machined within the annealed condition, it has a tendency to carry out higher within the cold drawn or warmth dealt with condition. Depending at the customer's end-use requirements, cutlery alloys such as these Stainless Steel WNR 1.4438 Sweepolet are typically decided on with appreciate to warmth treating response, mechanical properties and fabricating characteristics. The addition of columbium produces a stabilized kind of retailers that removes carbide precipitation, and consequently, intergranular corrosion. The additions of these factors sell progressed inter-granular corrosion resistance.

Applications that continually used these products include: Heavy responsibility exhaust systems, High temperature chemical processes, General refinery piping, etc. They also are utilized in Heat exchanger tubes, High stress steam pipes, High temperature steam service, Radiant super-heaters, and so on. Other applications are boilers, jet engine parts, exhaust manifolds, mufflers for huge engines and different numerous welded parts. 317L Stainless Steel Nippole is columbium stabilized austenitic steel plate with accurate fashionable corrosion resistance and really higher resistance in sturdy oxidizing conditions. It is weldable with the aid of using not unusual place fusion and resistance methods.

Material Specification Chart of SS 317L Olets

| Specifications | ASTM A182/ ASME SA182 |

|---|---|

| Dimensions | ASME / ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Size | 1/8"-4" (DN6-DN100) |

| Connect Type | Welded, threaded, BW, SW |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized Manufacturer of | Weldolets, Threadolets, Sockolets, Elbolets, Elbolets, Nippolets, Lateral Outlet, Coupolet, Flexolet, Sweepolet, Brazolet |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

SS 317L Olets Manufacturing Standards

| ASTM A182/A182M | Wrought Austenitic SS 317L Outlet Fittings |

|---|---|

| ASME SA182 – ASTM A182 | Standard Specification for Wrought Austenitic Stainless Steel 317L Outlet Piping Fittings |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

| BS3799 – | Specification for Outlet Fittings for the petroleum industry |

| ASTM A182 – ASME SA182 | Standard Specification for Wrought Austenitic SS Outlet Fittings |

| ASME Standard | ASME/ANSI B16.11, MSS-SP-97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Threaded, Welded, SW, BW |

Various Types Of 317L SS Olets

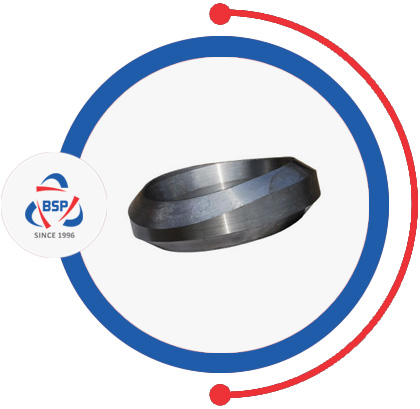

- 317L SS Weldolet

- UNS S31703 Weldolet

- Stainless Steel 317L Weldolet

- 1.4438 Welding Outlet

- SS 317L Welding Outlet

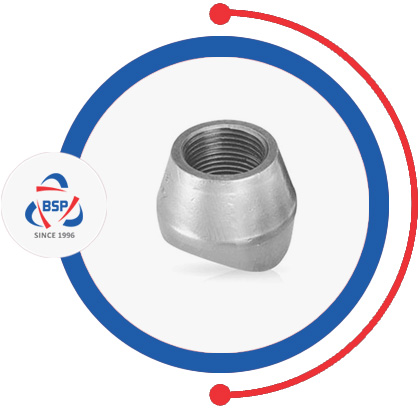

- 1.4438 Threadolet

- UNS S31703 Threaded Outlet

- 317L SS Threading Outlet

- Stainless Steel 317L Threadolet

- 317L SS Threadolet

- SS 317L Socket Weld Olets

- Stainless Steel 317L Socket Weld Outlets

- 317L SS Sockolet

- 1.4438 Sockolet

- UNS S31703 Sockolet

- 1.4438 Elbolet

- UNS S31703 Elbolet

- 317L SS Elbolet

- Stainless Steel 317L Elbow Outlets

- 1.4438 Latrolet

- UNS S31703 Latrolet

- 317L SS Latrolet

- Stainless Steel 317L Lateral Outlet

- 317L SS Nippolet

- Stainless Steel 317L Nipple Outlets

- UNS S31703 Nippolet

- 1.4438 Nippolet

- Stainless Steel 317L Flexolet

- 317L SS Flexolet

- UNS S31703 Flexolet

- 1.4438 Flexolet

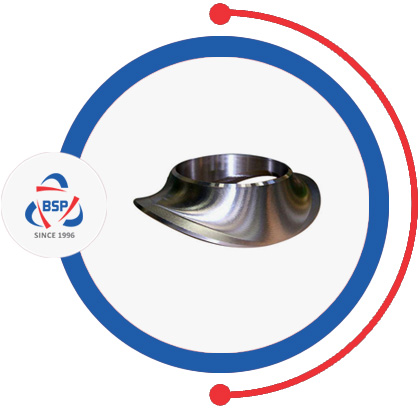

- 1.4438 Sweepolet

- UNS S31703 Sweepolet

- Stainless Steel 317L Sweepolet

- 317L SS Swept Outlet

- Stainless Steel 317L Brazolet

- 1.4438 Brazolet

- UNS S31703 Brazolet

- 317L Brazolet

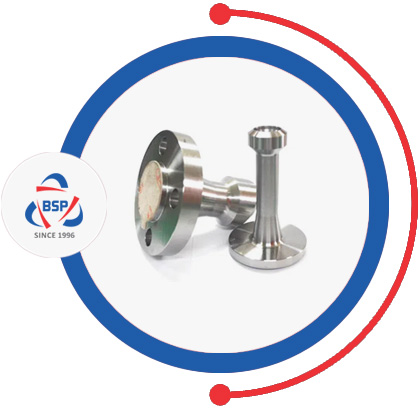

- 1.4438 Flangeolet

- Stainless Steel 317L Flangeolet

- 317L SS Flangeolet

- UNS S31703 Flangeolet

- Stainless Steel 317L Coupolet

- 1.4438 Coupolet

- UNS S31703 Coupolet

- 317L SS Coupolet

- UNS S31703 Insert Weld Outlet

- Stainless Steel 317L Insert Weld Outlet

- 317L SS Insert Weld Outlet

- 1.4438 Insert Weld Outlet

Equivalent Grades of SS 317L Olets

| STANDARD | WERKSTOFF NR. | UNS | JIS |

| SS 317L | 1.4438 | S31703 | SUS 317 |

View Thickness Table Of 317L SS Olets, We have Global sales network for Stainless Steel 317L Outlet Connection Fittings, Wide Stockist Of Werkstoff No 1.4438 Socket Weld Outlets In India.

Check available Sizes of ASME SA 182 SS 317L Branch Outlets Fittings, Ask For Ready Stock of UNS S31703 Threadolets in Mumbai, India.

BAGODA

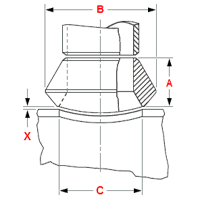

Quick ContactStainless Steel 317L Weldolet Dimensions

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1¼ | 1¼ 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1½ | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1½ 38.10 |

3½ 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2½ | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3½ | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2¼ 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8½ 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3½ 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13¼ 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23¼ 590.55 |

| NPS | A | B | C | D |

Stainless Steel 317L Sockolet Dimensions

| Nominal Pipe Size | Socket (C) Minimum |

Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | ||

| 1″ | 13 | 22 | 29 |

| 1/8″ | 10 | 10 | – |

| 1/4″ | 10 | 10 | – |

| 3/8″ | 10 | 13 | – |

| 1/2″ | 10 | 16 | 24 |

| 3/4″ | 13 | 16 | 25 |

| 1 1/4″ | 13 | 22 | 30 |

| 1 1/2″ | 13 | 24 | 32 |

| 2″ | 16 | 24 | 37 |

| 2 1/2″ | 16 | 25 | – |

| 3″ | 16 | 30 | – |

| 4″ | 19 | 30 | – |

Stainless Steel 317L Threadolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Stainless Steel 317L Nipolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Stainless Steel 317L Latrolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

Stainless Steel 317L Elbolet Dimensions

| Nominal Pipe Size | Face to Crotch (L) | |

| 3000 Lbs | 6000 Lbs | |

| 1/2″ | 25 | 32 |

| 3/4″ | 27 | 37 |

| 1 1/4″ | 33 | 41 |

| 1″ | 33 | 40 |

| 1/8″ | 19 | – |

| 1/4″ | 19 | – |

| 3/8″ | 21 | – |

| 1 1/2″ | 35 | 43 |

| 2″ | 38 | 52 |

| 2 1/2″ | 46 | – |

| 3″ | 51 | – |

| 4″ | 57 | – |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Ready Stock Stainless Steel 317L Olets

- ASTM A182 SS 317L Flexible Outlet

- 317L Stainless Steel Threading Outlet

- ASME SA182 Stainless Steel Threadolet

- Stainless Steel 317L Nipple Outlet Exporter

- Stainless Steel 317L Pipe Outlets

- SS 317L Olets

- UNS S31703 Olet Fittings

- SS 317L Branch Outlets Fittings

- Stainless Steel 317L Flangeolet

- 317L SS Insert Welding Outlet Manufacturer

- Stainless Steel 317L Branch Connection

- 317L Stainless Steel Sockolet

- SS 317L Sweepolet

- Stainless Steel 317L Threading Outlet

- SS 317L Weldolet Distributor

- Stainless Steel 317L Olet Fittings

- 317L SS Olets Manufacturer

- 317L Stainless Steel Welding Outlets

- SS 317L Coupolet

- ASTM A182 Stainless Steel 317L Flexolet

- 317L SS Brazolet Supplier in Mumbai

- 317L SS Insertweldolet

- DIN 1.4438 Socket Weld Outlets

- Stainless Steel 317L Industrial Olets

- SS 317L Olet Fittings

- ASTM A182 SS 317L Olets Branch Fittings

- Stainless Steel 317L Nippolet

- SS 317L Latrolet

- Stainless Steel 317L Outlet Fittings

- 5" Nb SS 317L Elbolet

- 317L Stainless Steel Outlets

- 317L Stainless Steel Coupling Outlet

Stainless Steel 317L Olets Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317L | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

317L Stainless Steel Olets Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |